Table of Contents

Many industries worldwide require air compressors to animate their businesses. For instance, the printing industry requires compressed air for equipment automation, running pneumatic tools, presses, packaging, and hoisting stereotype plates.

A reliable silent air compressor secures optimal value from compressed air systems. Somehow, however, leaks threaten the relevance of air compressors, often resulting in high costs without proper maintenance.

Meanwhile, identifying air leaks can save businesses money, while every system performs tremendously.

How Businesses Can Save Money from Air Leak Detection Examinations

1. Efficient Production

When your business employs a reliable service provider to detect air leaks, reliability and accuracy sets in. Moreover, production becomes efficient, warranty claims and repair costs reduce significantly.

What’s more? A business enjoys not serving customers with substandard products. For instance, after production, proper tests are conducted on the products while in the factory to identify defective products.

2. Refined Humanised Automation

Processes can be automated, but in the event of air leaks, expect sudden breakdowns. The manpower will increase, but when the automation is active, you can start the business with fewer and more professional manpower.

Furthermore, easy operation sets in, even with no skills. How about the working environment? Of course, it is highly enhanced in the process, making maintenance seamless.

3. Quality Standard

Air leak examination means detecting underlying problems that typically distort productive flow. When the leaks are contained and fixed, overall performance across the work site improves.

Meanwhile, you can comfortably quantify leak standards, reduce the rate of defective products, and rely on statistical data processing and analysis effortlessly.

4. Facility Inspection and Waste Mitigation

Schedule air leak maintenance checkups are critical whether there is a leakage or not. In this regard, your air leak detection examiner might discover frail spots that must be fixed earlier.

When air leaks without anyone being aware, it leads to wastage. So, a mere standard walkthrough of the business facility and relevant machinery discloses replaceable leaks that reduce air wastage.

5. Channel Expensive to Other Business Facets

Instead of losing money to repairs and wastage, air leak detection examination ensures claim reduction, and more money is saved. Of course, the company moves the funds to other sectors for continued productiveness. Meanwhile, channeling funds to different sectors improves the yield rate.

ELTEC warns that air compressor leaks can cost more than £1,000 monthly. The need for compressed air detection examination can’t be overemphasized, considering that simple, low-cost machine checkups save several thousand pounds.

How You Can Find Air Leaks

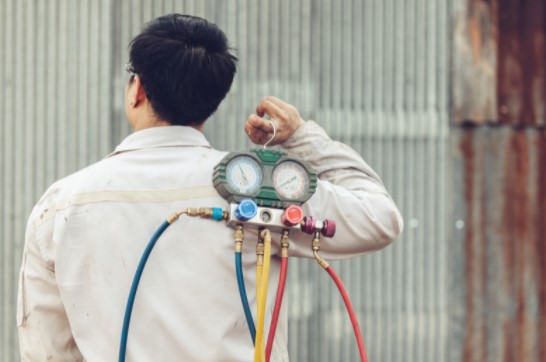

It is advisable to leave air leak detection to professionals. Nonetheless, you must know how to find air leaks, as shown below:

-

Pay Attention

First, you must be gravely attentive to the machines while running the air compressor. Do not enable the tools to lessen the noise. Meanwhile, it is advisable to run the inspection outside of working hours for improved low noise.

You want to listen and trace rasping or hissing sound. Make sure to inspect flanges, joints, and valves for air leaks too.

-

Inspect the Material or Machine

Typically, mixing washing liquid and water in a bowl. Next, work the mixture into a lather, and apply it to the pipework using a cloth or sponge. Pay attention to the valves, flanges, and joints too. Any portion that bubbles is the air leak spot.

-

Identify

Alternatively, you may use ultrasonic leak detectors to find air leaks. In the absence of ultrasonic leak detectors and on-site professionals, hire an air leak detection provider to detect the leaks easily. This air leak detection method may be done during working hours and with no disruption.

Selecting a Reliable Air Leak Detection Examination Provider

When your air compressor system is poorly maintained, the leak rate is higher, and you’d be losing energy and polluting the workstation. Thankfully, you can remedy this situation by requesting a specialist air leak detection examination.

A typical reliable air leak prevention program comprises leak tagging, tracking, verification, and compressor evaluation.

Also, pay attention to the customer service level. If you are not guaranteed 24/7 and a dedicated account manager, it may not be the best air leak detection program. Ultimately, regardless of your industry, make sure to engage in an aggressive and relentless leak prevention campaign.

Author Profile

- Blogger by Passion | Contributor to many Business Blogs in the United Kingdom | Fascinated to Write Blogs in Business & Startup Niches |

Latest entries

BusinessJanuary 9, 20266 Fastest Cash House Buyers in the UK 2026

BusinessJanuary 9, 20266 Fastest Cash House Buyers in the UK 2026 BusinessDecember 12, 2025The Smart SME’s Guide to Future-Proofing Physical Assets

BusinessDecember 12, 2025The Smart SME’s Guide to Future-Proofing Physical Assets FinanceOctober 28, 2025How to Measure the ROI of Your Promotional Product Campaigns?

FinanceOctober 28, 2025How to Measure the ROI of Your Promotional Product Campaigns? Home & LivingOctober 4, 2025Moving Forward When Leicester Family Dynamics Change

Home & LivingOctober 4, 2025Moving Forward When Leicester Family Dynamics Change